The Galien River Retreat in Michigan was awarded the prestigious Sansin Wood Design & Building Award. Watch this video to learn more about the project.

2024 Wood Design & Building Sansin Award Winner – Arbour House

Sansin recently awarded the Arbour House in British Columbia the coveted Sansin Wood Design & Building Award. Watch this video to learn more about the project.

How traditional timber frame companies incorporate mass timber successfully

By Mauraine Bos

As seen in Wood Design & Building

Increasingly, traditional timber frame companies are turning to large, prefabricated structural wood members for wall, floor, and roof construction. Using mass timber—including glulam, CLT, DLT, and NLT—in these applications allows the structural components to be revealed. It also exposes the beauty of the material and complements the other building elements traditionally seen in timber frame construction.

“For most timber framers, it’s a natural evolution into mass timber as you grow,” says Sigi Liebmann, a Swiss Master Timber Framer and founder of International Timberframes in B.C., who was part of a team that helped develop DLT in Switzerland in the 1990s. “As our client and contractor base expands, growing into mass timber is a natural evolution. The trend of mass timber helps with the shortage of labour, and it enables timber framers to use prefabricated wood rather than doing everything on-site. We’re used to prefabrication of components, and, in the end, it’s all piece-by-piece assembly.”

Peter Graul, president of Woodpecker European Timber Framing, a full-service design manufacturer in Alberta, has a lot of experience with CLT and glulam. One of his favourite types of mass timber, however, is DLT because it has no glue and is very price competitive. He says Woodpecker often uses a CLT panel as an exposed sheeting on top of a timber structure instead of a tongue-and-groove product.

“That’s typically where we would combine mass timber and solid sawn timber,” he explains. “It’s faster to install, and it gets the building weathertight more quickly. This feature has a more contemporary look because it doesn’t have the lines you’d typically see in tongue and groove.” Another way Graul’s company utilizes mass timber is within a timber frame construction that requires a big, long span beam that’s hard to get in solid sawn timber. “In this case, we will refer back to glulam to create the beams,” he explains.

Mass Timber Benefits

As the benefits of mass timber have become more truly understood and appreciated, mass timber’s use continues to grow. Here are just a few of its many benefits:

- Superior seismic strength due to its lightweight and flexible nature

- Excellent fire retardancy

- Quick and efficient installation

- A unique and pleasing aesthetic that creates a sense of warmth and well-being within the structure

- Exceptional strength

- Outstanding dimensional stability

But perhaps one of the greatest benefits of mass timber is its ability to mitigate and sequester carbon. It also generates almost no waste onsite. “What I personally like about mass timber is its sustainability characteristics,” says Graul. “We don’t have to use big trees to produce the wood. Also, it doesn’t come completely out of square and twist because there are several layers that are laminated to give the member stability. That is a big one for me as a carpenter.”

Liebmann says the benefits to working with mass timber extend into his workforce, too. “Most of the mass timber work—80% to 90%—can be done in the factory, which is a controlled environment. It’s easier on workers because they are able to stay home to prepare the mass timber in our factory, and then when the prefabricated product goes to the site, installation is easier on the workforce there as well.”

The number of sawmills near the shop enables International Timberframes to process all of its mass timber materials—a product they have dubbed Wood100 DLT—in the factory, so the volume of the shipment is smaller. “This leads to much quicker installation and ‘just-in-time’ delivery,” Liebmann says. “Contractors know the truck is coming and are able to lift the panels from the truck to be installed immediately. We just load the pieces onto the truck in sequence. It’s a big time and cost savings.”

Liebmann adds that this is a very familiar process for traditional timber frame companies. “With mass timber, it’s just bigger pieces, but it’s the same principles we’ve always had with timber frame,” he says. “We’re pretty flexible to mix solid timbers with mass timber. There is a material for every use, so it’s not a problem to mix and match.”

Protecting the Wood

To bring out the beauty of the wood and ensure it is protected during installation from UV and moisture, both companies protect all six sides of their mass timber elements with a factory-applied penetrating, breathable undercoat treatment from Sansin. “It’s very easy and quick to apply, and it’s totally worth it to protect the mass timber,” says Graul. “Mass timber projects are often bigger, so they will be exposed to weather longer. That makes it especially important to apply a protective coat.”

Liebmann says International Timberframes uses Sansin for its durability, ease of application, and range of colours and custom tinting that enables colour matching. “We also want to stay as environmentally friendly as possible, so Sansin makes sense for us.”

Sansin has developed a reputation for high-performance industrial and factory finishes that set the benchmark for environmentally friendly formulas. “Our coatings deliver the color, durability, and performance that architects, engineers, and builders can count on,” says Sjoerd Bos, managing director at Sansin. “In addition, our IRIS service takes pride in helping professionals select the best coatings systems to meet the aesthetics and protection requirements of each unique project.”

Along with protecting the wood during construction, the protective undercoat enhances the stability of the wood while preventing discoloration. It also increases the topcoat performance by helping control finish clarity, colour, and grain definition while offering deep wood protection against UV damage and moisture-related issues.

“Whether you’re working with a mass timber structure, traditional timber frame construction, or a hybrid, our best advice is don’t compromise on the coating,” Bos says. He notes that when mixing solid wood with mass timber, it’s important not to look for an exact match in the finish if the wood species are different. “Especially in a transparent finish, the colour will always patina a little differently based on the oxidation process, so it’s best in these instances to seek complementary colours and tones for the different types of wood.”

When using different coating formulas or applying the same coating to different species of wood, Bos suggests working with the coating manufacturer to obtain samples and ensure the appropriate colour and transparency are achieved.

The Versatility of Mass Timber

Mass timber offers incredible versatility for manufacturers, architects, and builders, and it is transforming what is achievable with wood construction. These timber frame companies have proven themselves to be mass timber “mix masters” that not only build remarkable structures with mass timber but also understand the value of protecting the investment in the wood.

To learn more, go to www.itimberf.com, www.europeantimberframing.com, or www.sansinfactoryfinish.com.

1. This structure is entirely mass timber with glulam and CLT post and beams on the exterior and CLT floors, walls, and ceilings. Everything was protected with Sansin finishes. (Courtesy of Woodpecker European Timber Framing)

2. The posts on the washrooms are solid sawn wood while some of the beams are glulam. The ceiling is mass timber. (Courtesy of Woodpecker European Timber Framing)

3. The beams and posts extending out of the building, as well as the railing posts, are solid sawn wood. The ceiling is constructed with CLT. (Courtesy of Woodpecker European Timber Framing)

4. This residential project features glulam and timber. (Courtesy of International Timberframes)

Deck staining mistakes – and how to avoid them (as seen in Cottage Life)

Between the BBQ, the patio furniture and family get-togethers, decks have to handle more traffic than any other wood surface around your house. Your deck is the centerpiece of your outdoor entertaining space, but it’s easy to make mistakes that can keep it from standing up to the summer sun, weather and foot traffic. Sansin – a company that has exclusively focused on eco-friendly wood protection solutions for 30+ years – offers these tips for ensuring your wooden deck is properly designed and protected so you can focus on relaxing with friends and family.

- Making bad deck design decisions. Excessive moisture is much more problematic for a deck than UV exposure. Wetting causes the wood to swell and then shrink while drying. From this natural expansion and retraction, little cracks will form as the wood cycles through these extreme conditions. This can cause the wood to discolor and the coatings to wear prematurely. Designing your landscape, sprinklers and roof drainage to avoid excessive wetting on your deck can help reduce these extremes and extend maintenance cycles.

- Choosing the wrong finish. Where many deck coatings easily peel and scratch, water-borne finishes (like Sansin’s Dec) penetrate wood tissue, protecting the wood from deep within, repelling water, while allowing the wood to “breathe“ naturally and not trap moisture.

- Applying product at the wrong time of day. Do your deck maintenance in the morning, out of direct sunlight. A deck that is exposed to sun or has been in the sun all day will be too warm. This can cause your product to dry too quickly on the surface.

- Not properly prepping the wood surface. Preparation is key to a successful deck project. First, apply a biodegradable deck cleaner (like Sansin Multi-Wash) to remove buildup, mold and mildew. Rinse with a hose, and let it dry thoroughly. Next, use an orbital sander with 60-80 grit paper to create a level, consistently porous surface. This will ensure the wood will accept the right amount of stain. Now, apply the stain using a garden sprayer and back brush any puddles of product, but let the stain soak into the wood. Allow the first coat to dry completely before applying subsequent coats.

- Not being proactive about maintenance. “Early bird gets the worm” is an appropriate saying for decks. Doing deck maintenance before visible wear and tear leads to a much easier and enjoyable experience. It’s important to inspect the surface carefully from time to time and look for even the smallest signs that maintenance is needed. It’s easier to put a maintenance coat on then have to redo a deck. Pro tip: do a simple water bead test to show if it’s time for maintenance. Apply a few drops of water to the wood. If it beads, your deck is protected. If the water soaks into the wood, it’s time for restoration.

- Assuming your deck will wear evenly. A deck may have a high traffic area that leads from the back door to a pool or a much-used lawn area. Alternatively, you may have a couple of areas that get sprayed by sprinklers or design issues such as downspouts or a clogged evestrough (gutter) can cause water to pummel parts of the deck during rainstorms.

In the case of uneven wear, putting a maintenance coat over the entire surface may not work to address specific, more acute wear issues. Instead, you may need to treat specific spots by sanding them and applying a first coat of stain directly to the bare wood. In the case of excessive wear, you might need to redo entire boards by sanding them down to bare wood and then refinishing them with a first coat before applying a second maintenance coat.

By remembering these common mistakes and avoiding them when you’re working on your DIY deck project, you will be one step closer to enjoying fun in the sun this summer without worrying about the condition of your deck.

4 Tips for Successful Wood Finishing

Wood is a beautiful, durable and versatile material, whether it is being used for millwork, cabinets, furniture, decking, or home construction. To help ensure lasting beauty and protection on your next wood project, follow these best practices.

Select a Suitable Wood Finish

Water-borne coatings are designed to penetrate deeply into the wood, rather than sitting on top, protecting wood from UV exposure and weather elements from the inside out. Water-borne finishes deliver outstanding color, durability and performance without the toxicity found in conventional stains. They are also easy to apply and maintain.

Prepare the Wood Surface

No matter the type of wood you’re working with, proper sanding is a critical first step to remove any mill glaze, open the pores, and allow the finish to penetrate. Use the proper equipment to evenly sand smooth wood the wood surface with 60-80 grit paper, and then use compressed air or a vacuum to remove the dust.

Follow Application Best Practices

Stir the water-borne product well (and continue to do so throughout the application process), ensuring there are no solids left on your stir stick. Test the color on a small, inconspicuous section of the wood to confirm you’re getting the look you want and the penetration the finish needs. Depending on the surface area you are coating, using a sprayer could be the fastest, easiest way to apply the product. For vertical surfaces, use a slightly upward angle and work section by section to apply the finish to the point of refusal from the bottom to the top. Use a high-quality brush to wipe away excess product, drips or runs. Follow the manufacturer’s directions on drying time before applying additional coats. Watch this video to learn more: https://youtu.be/n1QxTfRwWWk.

Be Proactive About Maintenance

The durability of a wood finish depends on many factors, including surface preparation, proper application, exposure to UV and moisture, the color of the finish (the darker the pigment, the more protection it offers), and the quality of the wood, just to name a few. As the maintenance time approaches, examine the surface of the wood every six months to check on the status of the coating.

Wood Finish and Treatment Decisions for Lasting Log Home Protection

Wood Finish and Treatment Decisions for Lasting Log Home Protection

Whether you currently own a log home or are purchasing or building one, you no doubt appreciate the enduring beauty of wood and the log home aesthetic. To protect your investment and ensure your home stands the test of time, you will want to protect it from dirt, moisture, UV exposure and other handling damage. This means wood treatment and finishing are critical decisions. Rather than choosing a coating that creates a non-breathable, waxy film on top of the wood, there are water-borne finish options that deeply penetrate into the logs, allowing water to evaporate and preventing moisture from getting trapped and rotting the logs from within.

Sansin Finishes: Eco-friendly & Durable

For more than 30 years, the Sansin Corporation has been exclusively dedicated to the development of enviro-friendly, water-borne wood finish technologies that make wood beautiful, durable and easy-to- maintain. Sansin’s wood coatings utilize a unique water-borne alkyd formula that combines the benefits of both oil- and water-based coatings but in a formula with much lower VOC (volatile organic compounds) levels.

Additionally, rather than using toxic dyes in the colorant system, Sansin utilizes nano technology to create pure pigments ground so fine that they deliver remarkably vibrant, uniform and long-lasting color. Because the finishes don’t form a film on top of the wood, the coatings won’t crack, chip or peel. Water-borne finishes also dry faster, allowing additional coats to be applied in one day rather than waiting a day or two between coats. When properly applied, the coatings offer superior UV protection and lasting durability that enables log home owners to extend the time between maintenance coats.

Sansin Products for Log Homes

Sansin recently launched an enhanced formula for its flagship Classic 1-2-3 wood protection system, which is specifically developed for logs and big timbers. Because of its penetrating nature, Classic 1-2-3 can dive deeper into the wood and help stabilize it while preventing cracking and checking as the logs dry out. The system creates a natural, low-luster finish in three formulas that will lighten, not go dark, over time:

- Classic 1: A deep penetrating, tintable base layer for natural wood tones and translucent colors, which offer even color and long-lasting protection.

- Classic 2: A penetrating, tintable formula that may be used as a second coat for natural wood tones and translucent colors or as the first coat for saturated and ultra-saturated colors. This coat offers enhanced weather and UV protection.

- Classic 3: A tintable formula that defines the wood grain and provides enhanced color, tone and UV protection with a beautiful low-luster fin It is the final coat in the Sansin Classic system – and can be used as the maintenance coat.

Sansin SDF is the company’s most versatile exterior finish and, in addition to log home restoration projects, works well on decks, docks, siding and fences. SDF’s specially-formulated oils and resins penetrate into the wood, creating a monolithic bond for outstanding weather and UV protection that won’t crack, peel or blister. SDF can be used on horizontal and vertical wood surfaces and is available in a wide range of natural, semi-transparent and even solid colors. Because SDF is designed to be highly water-repellent, it’s a natural choice for log homes in moisture-rich environments.

SDF Topcoat offers additional durability and superior water repellency using a semi-film forming finish. SDF Topcoat is great for surfaces where water splash-back causes discoloration due to moisture intrusion or frequent wetting.

When it comes to protecting wood during construction, Sansin Foundation, a nearly invisible penetrating base coat, is simply the best way to protect logs from damage during construction. Just give the wood a light cleaning, and then you can also use it as a base coat for Classic or SDF, creating those lighter, more natural tones but with built-in UV protection. Foundation penetrates into the wood, creating dimensional stability while reducing checks and wood movement. It is available in three tones that complement the wood species of fir, cedar and lightwood.

Look no further than Sansin Timber-Tec for your in-yard protection. Timber-Tec is an industrial grade product that protects from UV degradation, blue stain and repels water (helping wood dry), and it also mitigates wood discoloration during the construction process. Timber-Tec can be applied to green or seasoned logs, improving dimensional stability and allowing wood to adjust gradually to moisture levels in the environment. It comes in in two formula options. M-30 provides the natural light color of fresh pine while C-20 is a clear concentrate that provides a light honey color to the wood after it dries.

How to Maintain and Restore a Deck Showing Uneven Wear

Remember the ‘Early Bird Gets the Worm’ phrase? Well, that applies to proactive deck maintenance, as well. Deck maintenance before visible wear and tear leads to a much easier and enjoyable experience.

No matter what kind of wood you’ve chosen for your deck, all decking requires a maintenance coat of finish to maintain beauty and the highest level of protection. In most cases, a simple water bead test will show if it’s time for maintenance. And, in many cases, a simple wash and maintenance coat are all that needs to be done.

However, the wear on a deck can be uneven, and differentiation in wear becomes clearly visible when timely maintenance is not done.

Issues that Impact the Maintenance Cycle

It’s important to inspect the surface carefully from time to time and look for even the smallest signs that maintenance is needed. For example, a deck may have a high traffic area that leads from the back door to a pool or a much-used lawn area. Alternatively, perhaps a couple of areas see excessive wetting from sprinklers.

Other design issues might cause trouble. Downspouts or a clogged evestrough (gutter) can cause a waterfall to constantly pour water onto an area of the deck during times of precipitation. Other areas may get more wear from higher than normal exposure to rain, snow, sun or foot traffic. Remember, excessive wetting (moisture) is much more problematic than UV exposure. Wetting causes the wood to swell and then shrink while drying. From this natural expansion and retraction, little cracks will form as the wood cycles through these extreme conditions. This causes the wood to discolor and the coatings to wear prematurely. Designing the landscape and roof drainage to avoid excessive wetting can help reduce these extremes and extend maintenance cycles.

In the instances above, putting a maintenance coat over the entire surface may not work to address specific, more acute wear issues.

Deck Case Study

The following deck maintenance example shows how to both restore and maintain areas on the same deck that show uneven wear.

Deck Situation:

A southwest facing, 1,200 square foot cedar deck in London, Ontario, Canada, was finished with one coat of Sansin Dec in Espresso and one coat of SDF Topcoat Espresso in April 2016.

Sansin’s Dec product is a penetrating finish that works well for wetter wood situations. Normally, Dec is a 2-coat system. However, in this instance, the owner wanted a fuller finish and therefore, selected Dec as the first coat and SDF Topcoat as the finish coat. This deck ranges from sitting on ground level to a maximum clearance of 12” from ground level in an area (London, Ontario) that is considered an extreme climate for decks. It lies at the latitude of 42.5 degrees near to the Great Lakes, which brings large seasonal temperature and climate contrasts with lake effect moisture and snow. (Photo #1)

Maintenance Inspection:

After two years, in April 2018, the deck looked to be in good shape – and perhaps at most would need a simple cleaning. But, after more thorough, careful examination, a small area along the garden – where the sprinkler wets about three feet in on a daily basis – small checks (cracks) were noticed. It was clear by May of 2018 that a simple maintenance coat would be necessary to protect these newly opened surfaces.

As it turned out, to the owner’s regret, the maintenance of the deck was put off until September of 2018 (Photo #2). That meant the deck was into a third season of sprinkler wear and tear.

While 95% of the surface still looked great, the area that was wetted daily had started to discolor around the tiny checks. Also, some areas near the end grain were showing signs of moisture intrusion and swelling and contraction. (See Photo #3)

Had the deck been maintained in Spring of 2018, then a maintenance coat would have been sufficient. Waiting just four months longer caused two areas to need more corrective treatment, turning a half-day job into a two-day job.

The plan now was to both 1) correct the high wear areas that were left too long, 2) and maintain the other areas with the normal maintenance coat using SDF Topcoat.

Step One – Clean Deck and Prep Surfaces

For maintenance coat preparation, the owner used Sansin Multi-Wash. You can apply Multi-Wash with a scrub brush. Once the cleaner has been applied for the recommended period of time, rinse off the deck with a hose. Use a lot of water, but then let the deck dry thoroughly. (See Photos #4 and #5)

Step Two – Corrective Action on Worn Spots

Before putting a maintenance coat over the entire surface, it was evident that one cedar plank was showing more discoloration around little cracks from excessive moisture (swelling and contraction) or insufficient coating.

(Photo #6) the decision was made to redo this board that showed signs of wear down the middle of the wood. The grayer wood and slight yellowing show that insufficient coating was applied. This can be due to improper preparation or application, or sometimes a board can be of poorer quality and wear faster. In this instance, the owner can’t spot treat, but will instead sand the board down to bare wood with 60-80 grit paper and refinish that board with Dec and SDF Topcoat.

Once the entire deck is topcoated, it will blend and you will not be able to notice a difference in color or clarity. (Photo #7) On other areas, a spot treatment was necessary. One area was damaged by a sprinkler that drenched certain boards, leading to discoloration and calcium deposits from water pooling.

In this heavily wetted area by the sprinkler it was clearly visible which end grain surfaces were not protected. The end grain of wood absorbs moisture more than twenty times faster than perpendicular to the grain. It is important to protect end grain properly.

After carefully sanding the specific spots with 60-80 grit sandpaper (See Photos #8 and #9), Dec Espresso stain was applied directly to those bare areas with a China bristle brush (Photo #10).

Using a strong color formula would better match the color as penetration is less when scuff sanding compared to random orbital sanding. The product was left to stand wet and soak into the bare wood because applying to the point of refusal would match the color with the previous applied products.

After letting it sit, excess product was brushed away, leaving about 4-5 wet mil of Dec remaining (Photo #11). They were careful to wipe product away from the intact coating around the bare spot.

The newly stained area was then scuff sanded (220 grit) to prepare for the SDF Topcoat. This coat was applied in a similar way to the first, but allowed to blend in to the surrounding, intact coating area.

Step Three –

Now that the corrective staining was complete, a maintenance application of SDF Topcoat was applied to the entire deck. SDF Topcoat was applied with a 6” Corona brush. (Photo #12)

Results and Looking Ahead

The completed cedar deck is now ready for two or more years of protection. The owner will now be more careful about ensuring the sprinkler system does not hit parts of the deck leading to faster wear – and keeping the gutters clean.

The takeaway here is to apply a maintenance coat before more serious corrective action is needed. As the example showed above, waiting one season too long can make all the difference.

PRODUCTS USED IN THIS ARTICLE

Dec

Penetrating two-coat protection for decks.

Perfect for all kinds of wood – pressure-treated, cedar, pine and more. Easily applied, easily maintained, exceptionally beautiful. Won’t crack, peel or blister.

SDF Topcoat

Enhanced protection in either clear or solid color.

For additional protection, topcoat with this clear base tinted to your project specifications. Enhances base coats with a more saturated, finish in either clear or solid color formulas.

Making A Bee Line For Lumber

By Dr. Nenad Vidovic

Head, research and development department, The Sansin Corporation

The type of carpenter bees that homeowners have to worry about are large species (20 to 30 mm) with a smooth and shiny, metallic blue-black abdomen (bumble bees have a yellow and hairy abdomen and do not bore into wood).

Large carpenter bees prefer to bore into fir, spruce, pine, cedar or douglas-fir, but are known to attack many other species.

WHAT IS THAT EATING MY LUMBER?

“I was impressed by reading your recent article on mold [The SANSIN REPORT, (October 1999)],” a Toronto customer told us over the phone, “but I am having another problem.”

He accused a “bumble-bee resembling bug” of eating into his cedar deck. This called for an on-the-spot investigation so we arranged for a visit in May.

WHAT WE FOUND

Our customer had enhanced his beautiful brick house with a lovely cedar deck looking out over a backyard full of flourishing plants and a few cherry trees.

The rafters of the deck were peppered with 17 insect holes, and it was not difficult to determine that the culprit was, in fact, THE LARGE CARPENTER BEE, one of the most common wood-boring insects in North America. Some male bees buzzed around us in an attempt to guard their “territory,” while females were busy moving in and out of the galleries.

The bees evidently enjoyed boring through this $5000 cedar deck — “whenever we are sitting out here, they fly around and threaten to sting us,” our customer related. “We have sprayed the holes with different liquids, but the bees just look mad and return a few days later, drilling even more holes in the deck.” He enthusiastically accepted our offer to use the deck as a field test for our eradication methods.

MOTHER NATURE’S MIRACLES

Mother Nature does not allow organic material to last indefinitely. Otherwise, we would soon be engulfed in a thick layer of the organic stuff and life on the Globe would die out, due to the lack of important minerals. Microorganisms are the main tool that Mother Nature uses to breakdown organic material. When she uses this “tool” to attack valuable lumber, we must protect it. One effective method is to keep the wood dry, because microorganisms cannot go to work without water. But, alas, Mother Nature has developed another group of creatures to devour organic material; namely, dry-wood insects. Most of the beetles in this group, such as the powder-post beetle, the deathwatch beetle, the long-horn house beetle and termites, feed and nest in dry wood, while others, including ants and carpenter bees, use dry wood only for nesting. Even dry wood insects need some water to propagate. They get it by devouring the wood. As each cellulose chain in the wood is broken apart in the insects’ stomach, a molecule of water is generated, producing enough moisture for the insects larvae to live happily in the dried wood. No one could ever accuse Mother Nature of lacking ingenuity especially if the wood is left unfinished. Outdoor structural timber such as porch and deck components, window sills, wooden sidings, eaves, fascia boards, garage and shed components are the most vulnerable; but carpenter bee galleries are also found in posts, transmission poles, timber bridges and dead trees.

After the bees mate early in the spring, they make a bee line for wood in search of a home for their “babies”. Females are usually very busy. Several generations may use old tunnels for many years, but most often are obliged to bore new ones. Male bees are not just couch potatoes. They fly around, guarding the nests. If a person or some other outsider shows up, they become aggressive, making rapid flights around the intruder and threatening to sting. Ironically, they have no stinger. The females have a stinger but are non-aggressive and will not use the weapons unless they are repeatedly provoked.

Upon finding a convenient location for a home, females begin excavating. They bore perfectly round holes about the size of a dime as far from the ground as possible.

Overhanging timber is a favorite site. Wherever possible the bees bore the holes on the bottom surfaces. They instinctively avoid areas that are vulnerable to water seep when it rains and prefer “sky highs” that are less attractive to ants, termites and other enemies. The main entrance to a bee gallery is oriented across the grain and is up to two inches deep. The bees then start tunneling at 90 degrees, along the grain, making the main, family tunnel.

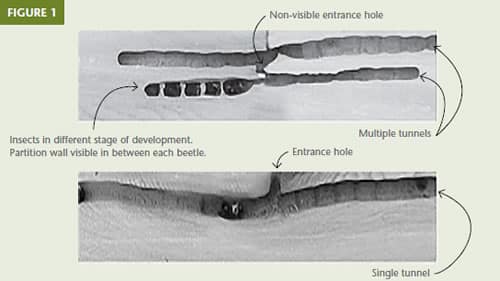

These are usually about one foot long, but can reach several feet, especially after years of use. Multiple tunnels are also common (Figure 1). If entry occurs through the end of board or log, there is no right angle turn; the bees simply make straight-line tunnels with the grain.

Once the gallery is ready, the female begins laying eggs, starting from the deepest end of the tunnel. She uses wood sawdust to cache walls between the eggs, so that each egg is partitioned in a separate chamber (Figure 1). When the larvae hatch, they feed on parental food (pollen and nectar based) and grow into juvenile (unmated) adults. They may emerge in the fall in search for more food, but return to the galleries to hibernate. Early in the spring, the adults emerge, mating follows and so the life cycle goes on. By mating time, the parents have died. One female delivers a generation of up to eight bees once a year. Some species produce two generations, especially in warmer regions.

DAMAGE TO THE WOOD

At first sight, the only evidence of attack are the entry holes made by the females. Damage is minor if infestation occurs only in decorative wood such as trims, fascia boards or sidings. If structural lumber such as in joists, windows, beams, shingles or logs is attacked, costly repairs are often necessary, especially after several years of neglect.

The presence of carpenter bees in wood sometimes attracts woodpeckers looking for larvae. The resulting damage can be extensive, especially when the hungry birds go after the bees from one chamber to another in the wood.

OUR TREATMENT

After we spotted the holes in broad daylight, we came back and monitored the insects at dusk as they were turning

in for the night. As soon as most of them seemed to have returned to the galleries, the action began. We saturated each hole with an aerosol type of insect spray containing 1% Diazinon insecticide.

As the treatment began, dazed bees emerged from the galleries, flew around erratically and fell to the ground, dying. By 11 pm, we counted 12 dead bees and found three more in the morning. After seven days, the score was 36. The aerosol spray treatment was then repeated. Finally, we injected a 100% solids, water free chinking compound into the holes and sealed them with tapered corks to retain the gases inside the galleries and to keep track of the holes that had been treated. The compound increases the kill ratio, prevents insects from re-entering, and keeps wood peckers away from the holes.

We made a final inspection in July 2000. No bees were observed flying around. After dismembering two joists to register the size of the galleries, we were surprised to find nine more bee carcasses in each joist (Figure 1).

WHAT YOU CAN DO

If bees are buzzing around, follow their flight to entry holes. Always inspect your lumber for the presence of holes at least once a year, preferably in the spring. Look for a sawdust-like frass that may accumulate on the surface below entry holes. If the frass looks like freshly sawed wood, the insects are probably still alive and active. Old frass is grayish in color. It indicates that adult insects have fled the scene and that mated females have probably not taken the same gallery to develop their own generation. Check for insect activity by placing folded paper (a tissue is suitable) into the holes and seeing later if it has been pushed out. Should eradication be necessary, make sure that the insects are back in the gallery at the time of action (if females survive, they will construct a new gallery). Modern (leadfree) paints and stains will deter the bees but not forever. Even pressure treated wood can be attacked (Henning 1999), so it is wise to apply wood stains.

Any insecticide that targets carpenter bees on the label can be used for eradication. Look for a product in a container with a flexible straw, so the liquid can be injected beyond the entry curve, directly into the main gallery. Powdered insecticides also do a good job.